Company Overview

Matchwell Engineering Pvt Ltd

- 25 Years experience in manufacturing engineering goods & manufacturing fuel injection lines brakes pipes & fuel lines for Petrol & Diesel engines for automobiles, Tractors, Stationary engines, Railway & General engineering.

- 100+ Trained Workers Including Certified Welders and Skilled Engineers Capable of Producing World-Class Products.

- Processing @12000+ T Capacity for Fabrication.

- Presence Across in Construction Equipment, Infrastructure Industry, Mining Equipment & Road Construction.

A brief intro to Matchwell Engineering Pvt Ltd

Matchwell Engineering Private Limited – Service Provider of mcc control panel room design, mechanical engineering & petrol pump structural engineering in Pune, Maharashtra. What started off as an entrepreneurial venture three decades ago, is today India’s most successful company in the field of mechanical engineering with presence all over the world.

Why Matchwell Engineering Pvt Ltd ?

Quality & Quality Assurance

Manufacturing & Production

Highly Cost-effective

Our Clients

A true partnership is a two-way street — ideas and information flow openly and regularly, based on a foundation of mutual trust and respect for one another’s expertise — and our clients embrace this philosophy.

Matchwell Engineering Pvt Ltd

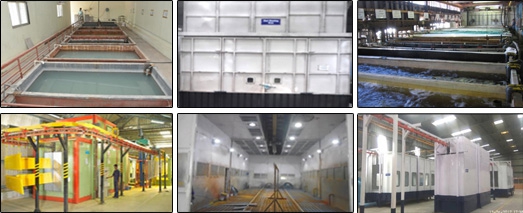

Our Infrastructure

7 Tank Pre-Treatment Process. / Pre-Treatment Type :

7 Tank / No. Of Baths : 7 / Chemical Make : Henkel Make.

Shot Blasting / Length :- 12 Mtr. / Width :

– 5.3 Mtr. / Height :- 5 Mtr. /Lux Level :- 600 to 650 Lux.

Conveyorised Paint Booth / Length :

– 22 Mtr / Width:- 3 Mtr. / Height:- 2.5 mtr. / Lux Level :- 1000 Lux. /Water Screen Down Draft

& Pressurise

Liquid Paint Booth / Length:

– 12 Mtr. / Width:- 5.3 Mtr. / Height:- 4 Mtr. / Lux Level :- 1000 Lux. / Down Draft Water Base.

Plasma Make :

Messer HD Plasma / Bed Size : 4.5mtrX16 mtr. / No. Of m/c’s : 2 No / Power :- 260 Amp. / Plasma Capacity :- 32 mm Max. / Oxy Fuel Capacity :- 90mm Max

CNC Turret Punch :

Amada / Bed Size : 2.5 Mtr X 1.25Mtr / No. Of m/c’s : 1 No / Max Thickness :- Up To 5 mm

NC Turret Punch :

Amada / Bed Size :3 Mtr. and Up To 6mm Thickness / No. Of m/c’s : 1 No. / Max Thickness:-Up To 6 mm

CNC Press Brake :

Hindustan / Stroke Length:: 9 Mtr. / No. Of m/c’s : 1 No / Max Thickness :- 16 mm.

Welding Stations :

+60 MIG Welding Stations. / No of Machine : +60 Mig Welding Machine. / Make: Esab Auto-k400 & 600 / Capacity :- 400Amp to 600Amp.

Matchwell Engineering Pvt Ltd

Our Infrastructure

7 Tank Pre-Treatment Process. / Pre-Treatment Type :

– 5.3 Mtr. / Height :- 5 Mtr. /Lux Level :- 600 to 650 Lux.

Plasma Make :

Messer HD Plasma / Bed Size : 4.5mtrX16 mtr. / No. Of m/c’s : 2 No / Power :- 260 Amp. / Plasma Capacity :- 32 mm Max. / Oxy Fuel Capacity :- 90mm Max

Shot Blasting / Length :- 12 Mtr. / Width :

– 5.3 Mtr. / Height :- 5 Mtr. /Lux Level :- 600 to 650 Lux.

CNC Turret Punch :

Amada / Bed Size : 2.5 Mtr X 1.25Mtr / No. Of m/c’s : 1 No / Max Thickness :- Up To 5 mm

Conveyorised Paint Booth / Length :

– 22 Mtr / Width:- 3 Mtr. / Height:- 2.5 mtr. / Lux Level :- 1000 Lux. /Water Screen Down Draft

& Pressurise

NC Turret Punch :

Amada / Bed Size :3 Mtr. and Up To 6mm Thickness / No. Of m/c’s : 1 No. / Max Thickness:-Up To 6 mm

Liquid Paint Booth / Length:

– 12 Mtr. / Width:- 5.3 Mtr. / Height:- 4 Mtr. / Lux Level :- 1000 Lux. / Down Draft Water Base.

CNC Press Brake :

Hindustan / Stroke Length:: 9 Mtr. / No. Of m/c’s : 1 No / Max Thickness :- 16 mm.

Welding Stations :

+60 MIG Welding Stations. / No of Machine : +60 Mig Welding Machine. / Make: Esab Auto-k400 & 600 / Capacity :- 400Amp to 600Amp.

Need Help with Easier Industrial Solutions? We Are Experts!

Founded in 1984

Opened In 2008

Prod. Started in 2009

Opened In Dec- 2015

Full Flush Prod, Started in Jan-2016

Mission & Vision

Matchwell Engineering Pvt Ltd

MISSION :

” To Achieve Excellence in all Aspect of Business to Meet and Exceed Expectations of Our Customers, Employees, Suppliers and Stake Holders. Creating Value to our Customers by Being Agile, Process Centric and Innovative.”

VISION :

“To Be the Most Admired Company to Our Customers, Suppliers, Employees and Stake Holders”