INFRASTRUCTURE

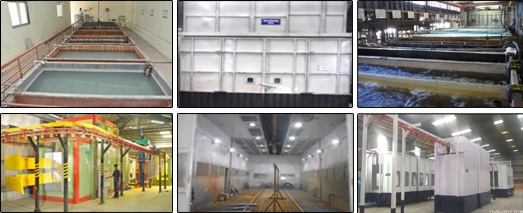

Surface Tretment

- 7 Tank Pre-Treatment Process. / Pre-Treatment Type : 7 Tank / No. Of Baths : 7 / Chemical Make : Henkel Make.

- Shot Blasting / Length :- 12 Mtr. / Width :– 5.3 Mtr. / Height :- 5 Mtr. /Lux Level :- 600 to 650 Lux.

- Plating Shop : Width – 1.5 Mtr. / Tank Length :- 10 Mtr. / Deep :- 1 Mtr. / Plating Method :- Trivalent Plating & Hexavalent Plating / No. of Tank :- 9 Tank

- Conveyorised Paint Booth / Length :– 22 Mtr / Width:- 3 Mtr. / Height:- 2.5 mtr. / Lux Level :- 1000 Lux. /Water Screen Down Draft & Pressurise .

- Liquid Paint Booth / Length :– 12 Mtr. / Width:- 5.3 Mtr. / Height:- 4 Mtr. / Lux Level :- 1000 Lux. / Down Draft Water Base.

- Conveyorised Powder coating Booth :Length- 60 Mtr. / Width:- 3 Mtr. / Height:- 4 Mtr. / Booth :- 2 no. / Oven :- 2 no.

- Plasma Make : Messer HD Plasma / Bed Size : 4.5mtrX16 mtr. / No. Of m/c’s : 2 No / Power :- 260 Amp. / Plasma Capacity :- 32 mm Max. / Oxy Fuel Capacity :- 90mm Max .

- CNC Turret Punch : Amada / Bed Size : 2.5 Mtr X 1.25Mtr / No. Of m/c’s : 1 No / Max Thickness :- Up To 5 mm

- NC Turret Punch : Amada / Bed Size :3 Mtr. and Up To 6mm Thickness / No. Of m/c’s : 1 No. / Max Thickness:-Up To 6 mm

- CNC Press Brake : Hindustan / Stroke Length:: 9 Mtr. / No. Of m/c’s : 1 No / Max Thickness :- 16 mm.

- Welding Stations : +60 MIG Welding Stations. / No of Machine : +60 Mig Welding Machine. / Make: Esab Auto-k400 & 600 / Capacity :- 400Amp to 600Amp.

- 3 Axis CNC bending : Model :- 65CNC3X-ES

- CNC Press Break :Yashikawa (Fronius Control) / Axis:- 5 Axis